XLANCE® makes anything elastic

from Polypropylene to extra white and non-iron clothing

Easy set

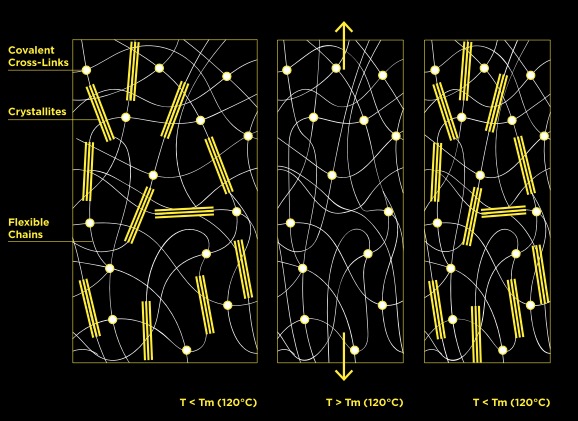

XLANCE® is heat set at 120°C, just above the crystal melting-temperature (against 185-190°C required for spandex). This is due to its molecular architecture and enables the combination with thermosensitive fibers, as well as guaranteeing significant energy and pollution savings.

- XLANCE®

- SPANDEX

XLANCE® makes elasticity durable

thanks to its unique chemical and thermal resistance

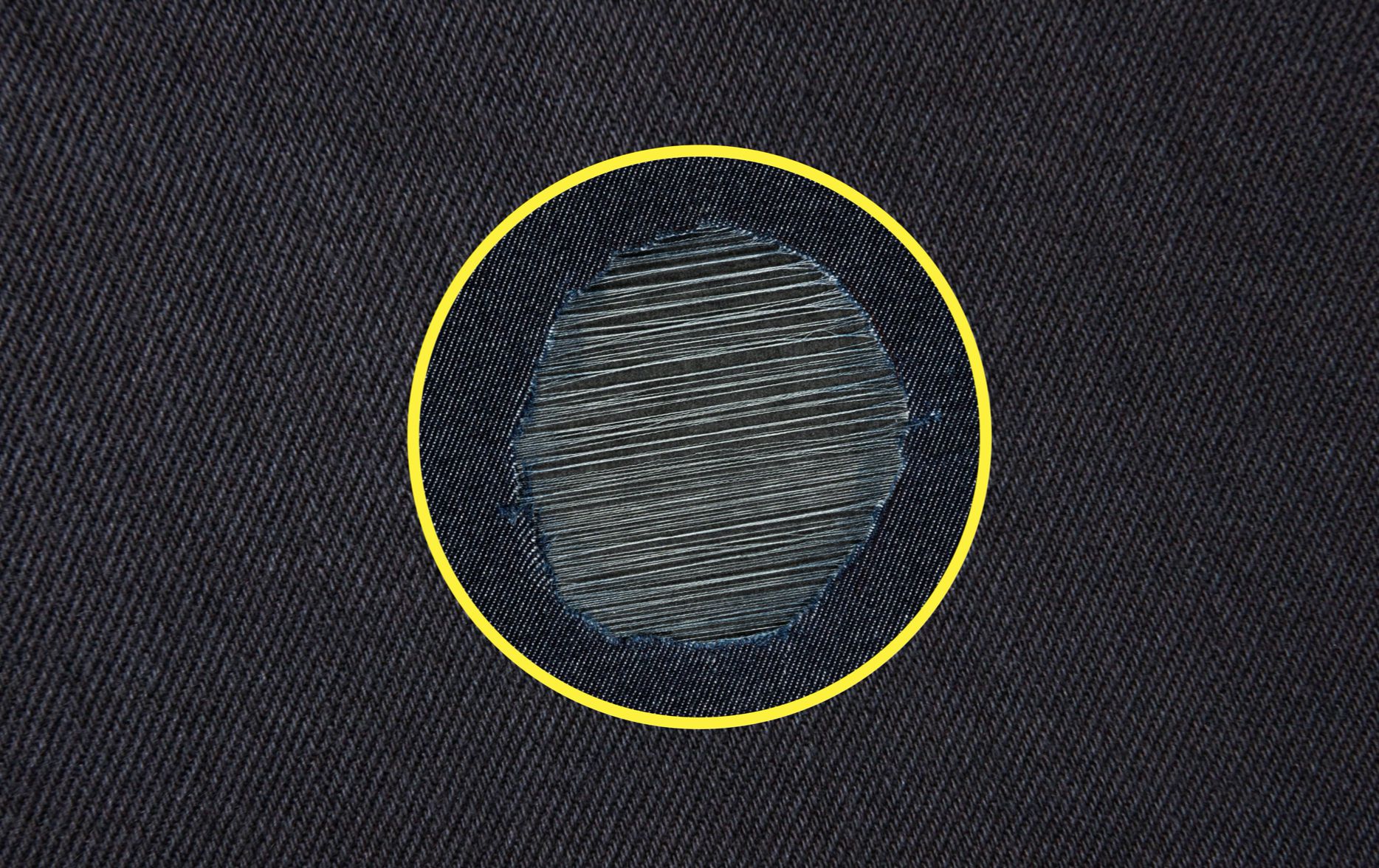

Acid test

1 ml of concentrated (98%) sulphuric acid was applied to the center of a denim fabric containing XLANCE® for 4 hours, before rinsing with water: XLANCE® yarn remains fully intact.

XLANCE® is characterized by the absence of any easily-attackable group in his polyolefin backbone and by the presence of the covalent crosslinks. This gives XLANCE® an excellent resistance to any aggressive chemical agents, such as strong acids, alkalis, oxidizing agents, enzyme wash conditions.

Heat test

XLANCE® can withstand temperatures up to 220°C without compromising its integrity and stretch performance thanks to the covalent crosslinks. This makes it suitable for high-temperature textile processes.

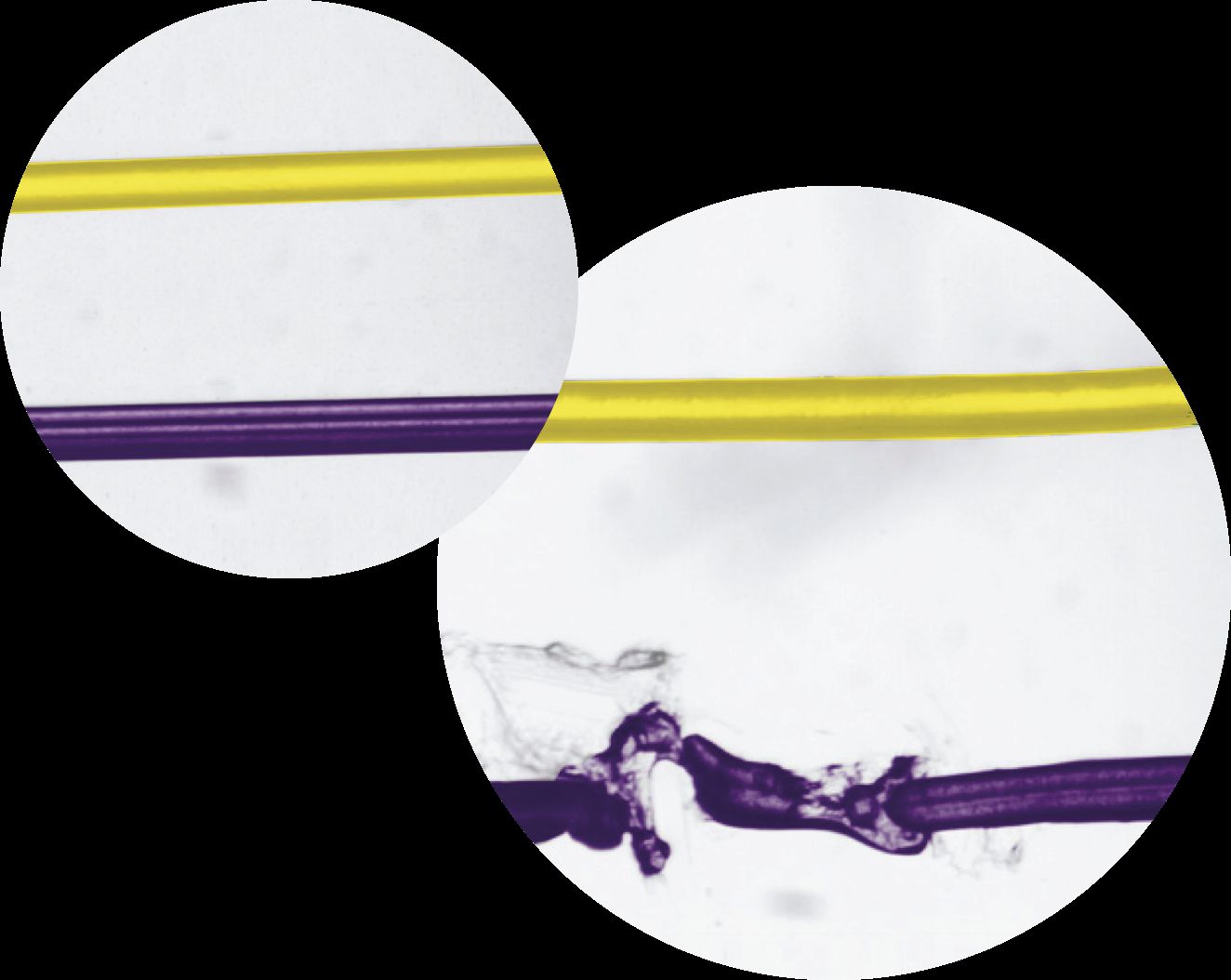

- XLANCE®

- SPANDEX

Before heat

treatment

After heat

treatment

After heat

treatment

Micrographs comparing XLANCE® and spandex fibers before and after 3 minutes treatment at 220 ± 3 °C. Fibers were placed on a slide side by side, covered with slipcover and placed on a hot stage. After cooling, the slipcover was gently removed, leading to the disintegration of spandex but not of XLANCE®.

UV test

XLANCE® yarn is inherently resistant to UVA and UVB radiations.

- XLANCE®

- SPANDEX

Stretch

test

XLANCE® features an innovative gentle stretch power, completely different from the typical high stretch power of spandex. The force required to stretch XLANCE® is much lower than the one to be applied to spandex. This accounts for the unique comfort stretch feeling of XLANCE® shaping fabrics.

- XLANCE®

- SPANDEX

behind Xlance®

The polymers

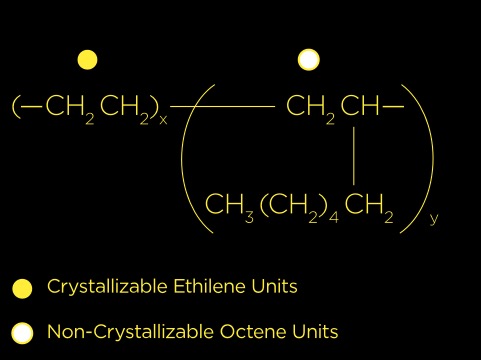

XLANCE® is a polyolefin-based elastic yarn. More specifically, it is based on copolymers of crystallizable ethylene and non-crystallizable 1-octene monomers. These copolymers, at the solid state, build an elastomeric network, where the crystallites serve as reinforcements and act as physical crosslinks to connect the flexible amorphous chains.

The links

After spinning, XLANCE® undergoes a process to form covalent crosslinks, with the aim to provide the fiber extra thermal stability and mechanical integrity beyond the crystal melting point (i.e. 120°C). Unlike the covalent crosslinks, which are permanent in nature, the crystallites serve as thermally reversible links: at temperatures above their melting point (i.e., 120°C), they disappear, enabling some degree of formability, and re-form upon cooling back, thus allowing fiber setting.